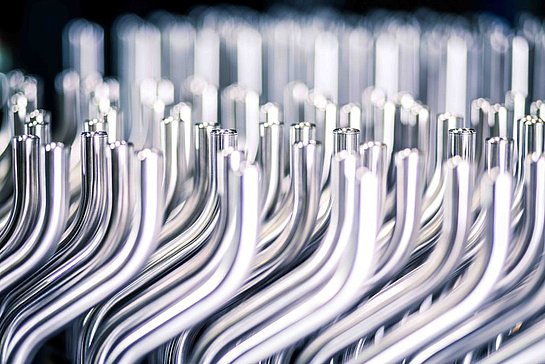

A product line that sets standards

The same applies to our stainless steel pipes as to all WECUBEX products: Only the best is good enough for us. This is why the technological and economic demands of our customers are the ideal driving force for the continuous optimisation of our development and production processes. Whether special geometries or the most demanding surfaces – our interaction of highly efficient systems, great passion and comprehensive experience ensures impressive solutions.

Therefore our laser-welded stainless steel tubes not only become functional premium products with an excellent price-performance ratio, but also guarantee efficient further processing. The result is satisfied customers for many years to come: They appreciate our consistent quality policy and confirm our strategy of marketing stainless steel tubes as semi-finished products for superior components.

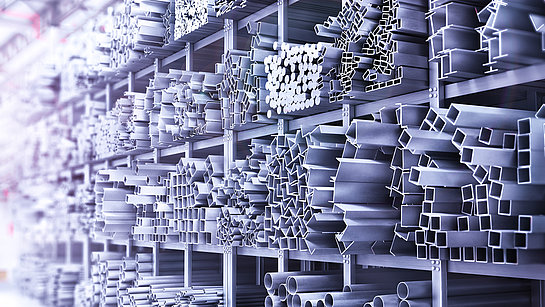

Our standard program:

Round tubes, elliptical tubes, oval tubes and profile tubes. In addition, we manufacture special profiles in a wide range of cross-sections and wall thicknesses with the narrowest tolerances and annealed tubes. In addition, we produce pipes with DVGW approval (line pipes for drinking water and gas) in the dimensions Ø 15, Ø 18, Ø 22 and Ø 28 mm. We have the DVGW type examination certificate for gas and water supply products.

Dimensions:

- Round tubes: diameter from 8 to 50 mm

- Elliptical tubes: external dimensions from 9 x 6 mm to 60 x 40 mm

- Oval tubes: external dimensions from 9 x 6 mm to 60 x 32 mm

- Profile tubes: external dimensions from 6.5 x 6.5 mm to 40 x 40 mm

- Special profile tubes: cross-sections from 12 to 70 mm

- Wall thicknesses: from 0.4 – 3.2 mm

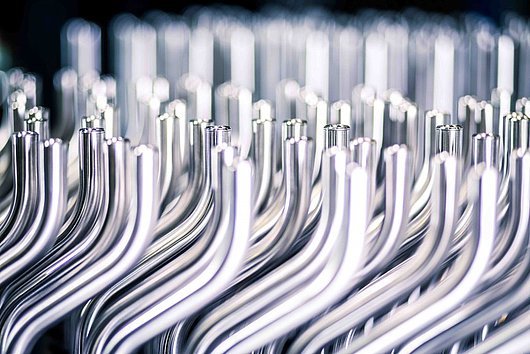

Special quality assurance procedures:

- WIG-/ TIG- and laser welding technology

- Inline eddy current testing

- Continuous inline pipe measurement

- Continuous inline roughness depth measurement

- Continuous inline gloss measurement

- Acceptance during production

- Narrowed pipe tolerances less than +/- 0.1 mm

- Wall thickness tolerances up to +/- 0.02 mm

- Weld seam position freely selectable

Request

Request