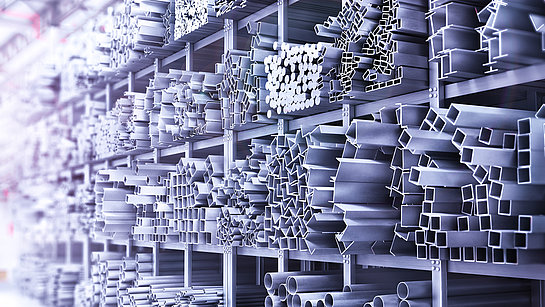

Stainless steel – a material for the highest demands

Stainless steel is a special material: customers associate it with both a superior appearance and excellent quality. The fact that this precious raw material costs many times more than conventional steel makes its successful processing a particular challenge.

WECUBEX has established itself as a true stainless steel specialist thanks to years of experience, state-of-the-art technology and constant further development of its personnel know-how. In many stainless steel processing industries we are the first point of contact.

Whether simple circuit boards or complex assemblies – our highly motivated employees manufacture unique products, always combined with a view to economic efficiency. The basis for this are the structured and efficient processes of our entire value chain as well as the dialogue with our customers: This is the only way to create optimal solutions.

Focus of our stainless steel processing:

- Laser cutting of sheet metal up to 4,000 x 2,000 mm and 25 mm thickness

- CNC punching up to 3,000 x 1,500 mm and 6 mm thickness

- Coil punching line for large series

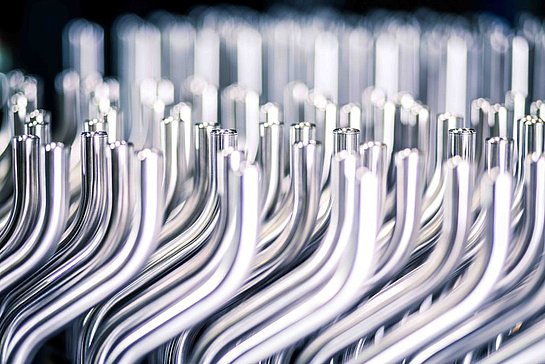

- Pipe production up to d = 50 x 3.2 mm (with laser, WIG/TIG)

- Comprehensive tube processing such as laser cutting, CNC bending, punching, end processing

- Manual welding/ spot welding etc. by certified welders

- Grinding, brushing, vibratory grinding

- Mechanical processing

Request

Request